SMT Workshop

SMT Workshop

SMT Workshop

SMT Workshop

SMT Workshop

SMT Workshop

SMT Workshop

SMT Workshop

SMT Workshop

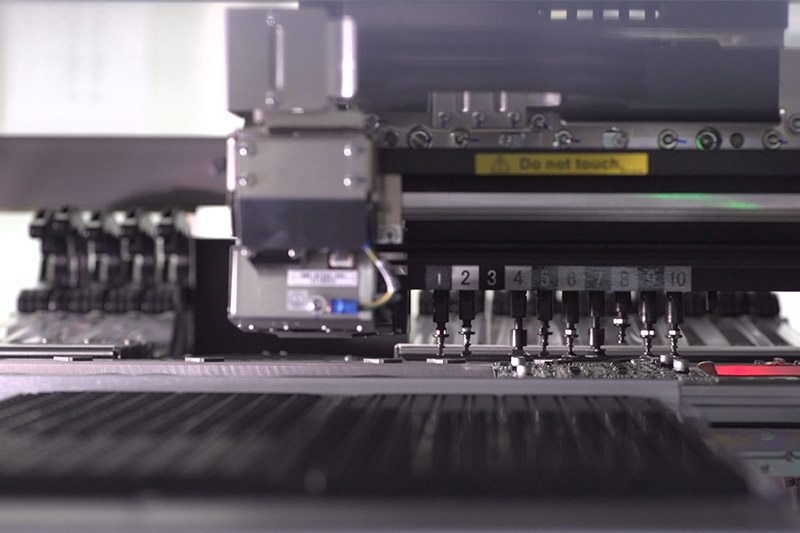

SMT solder paste automatic printing machine

SMT General Mounter

SMT automatic board feeder

SMT Automated production line

SMT QA

SMT QA

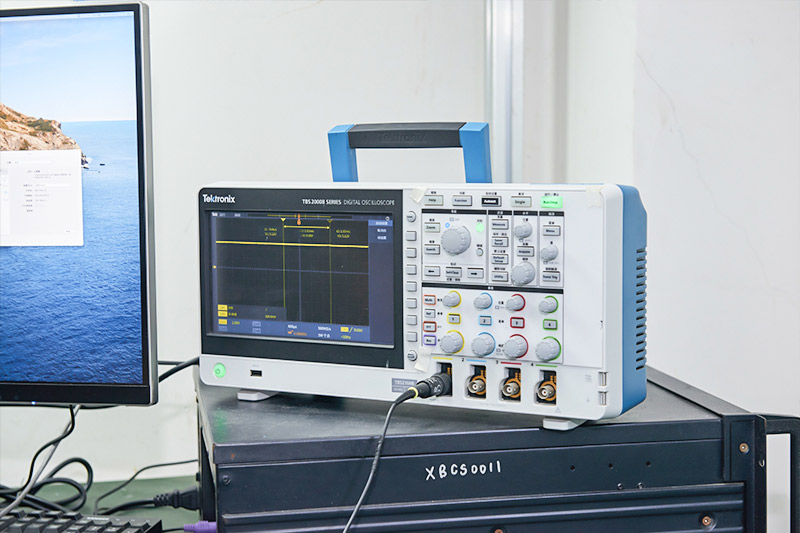

AOI Test

SMT Workshop

SMT Workshop

SMT Workshop

SMT Workshop

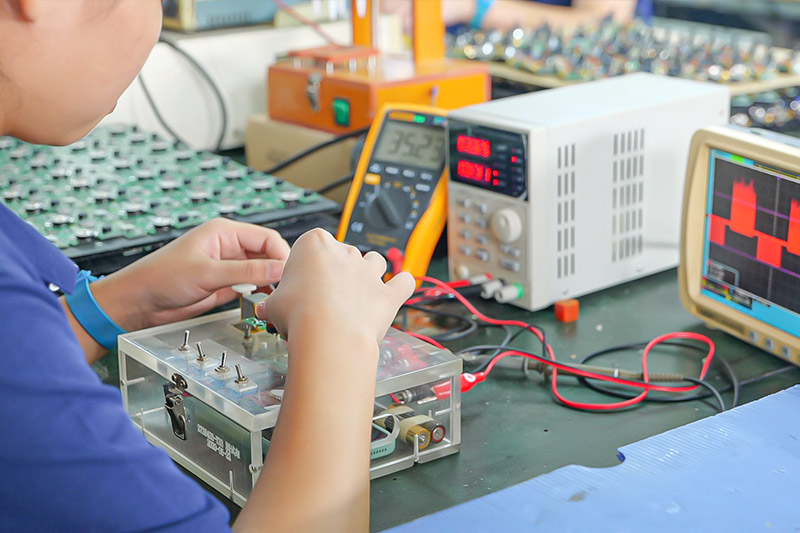

DIP Workshop

DIP Workshop

DIP Workshop

DIP Workshop

DIP Workshop

DIP Workshop

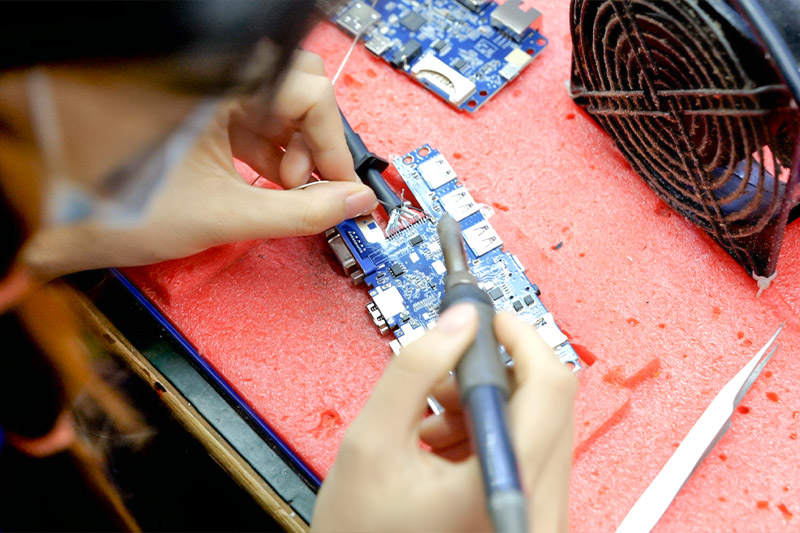

DIP Workshop

DIP Workshop

DIP Workshop

DIP Workshop

DIP Workshop

DIP Workshop

DIP Workshop

DIP Workshop

DIP Workshop

DIP Workshop

DIP Workshop

DIP Workshop

DIP Workshop

DIP Workshop

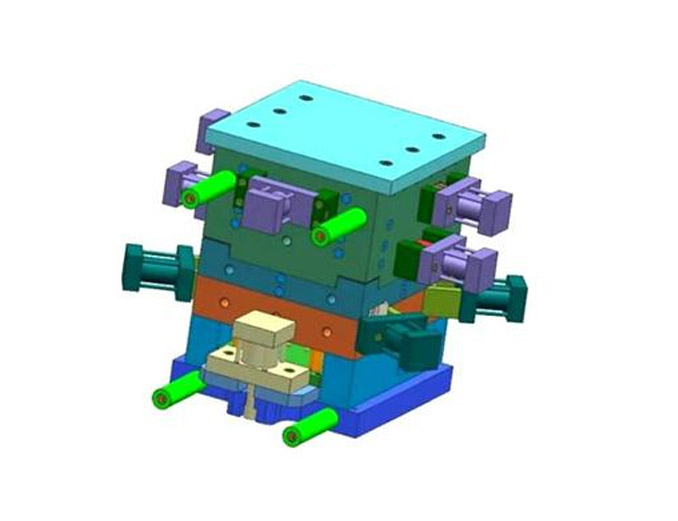

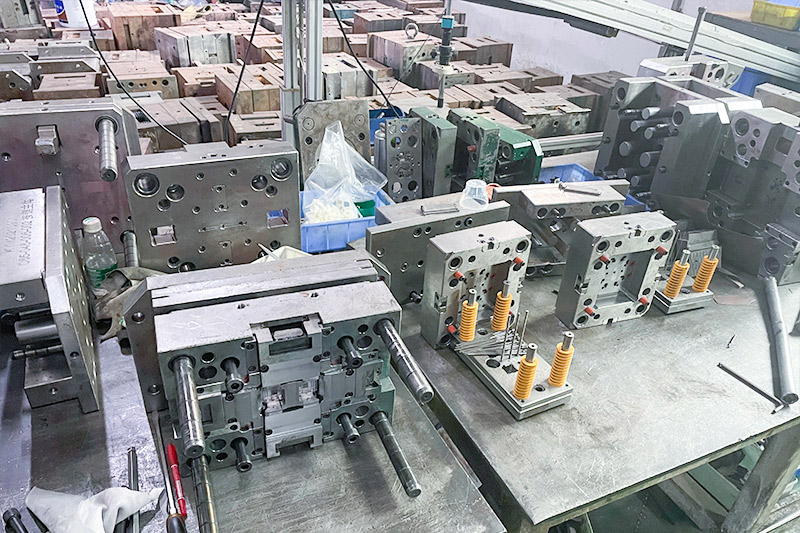

Mold Injection Workshop

Mold Injection Workshop

Mold Injection Workshop

Mold Injection Workshop

Mold Injection Workshop

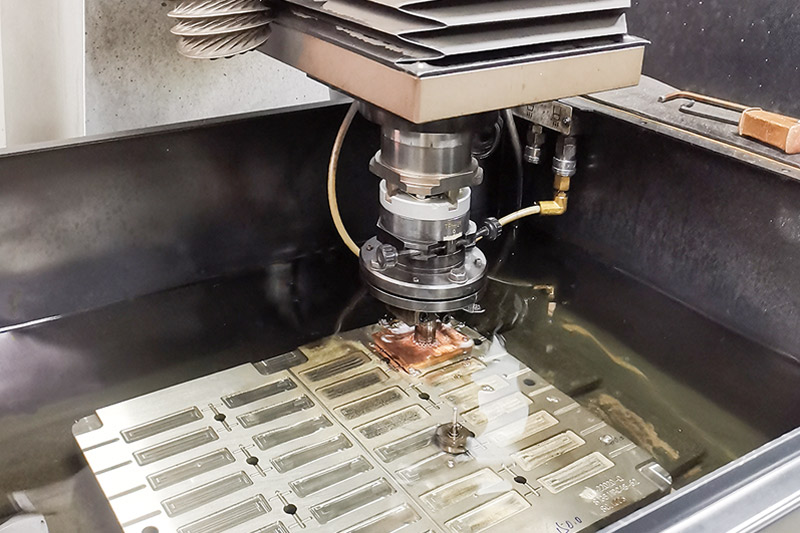

Sinker EDM machine

Sinker EDM machine

Mold Injection Workshop

Mold Injection Workshop

Mold Injection Workshop

Mold Injection Workshop

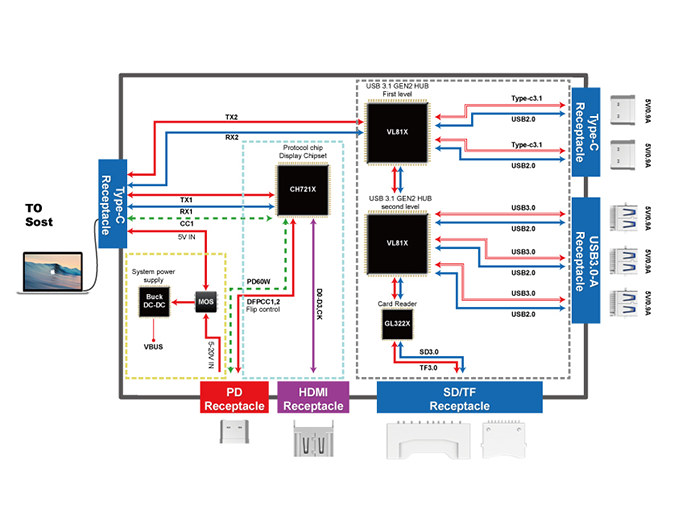

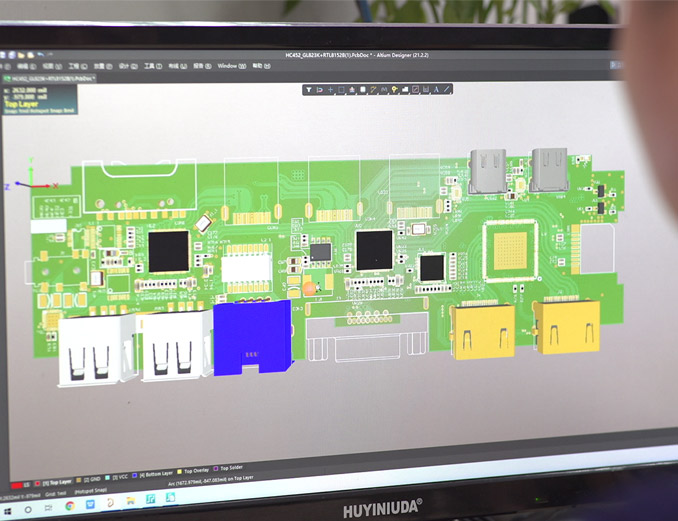

Hardware Workshop

Hardware Workshop

Hardware Workshop

Hardware Workshop

Hardware Workshop

Hardware Workshop

Hardware Workshop

Hardware Workshop

Hardware Workshop

Hardware Workshop