SMT Chip Processing

DIP plug-in processing

SMT patch proofing

Focus on non-consumer electronic products SMT patch processing, small batch

commitment Delivery is extremely fast and on time

after the materials are confirmed correctly

-

Product defect rate

Product defect rate

Less than 0.1% -

Adopt international

Adopt international

Imported equipment -

Strict control

Strict control

Guaranteed quality -

Fast proofing speed

Fast proofing speed

High product quality

DIP packaging technology

Skilled soldering iron hands with strict training, welding speed and quality are controllable

Strict IPQC and QA LOT sampling inspection standards to

ensure the reliability of DIP processing

-

Rigorous testing

Rigorous testing

Fully comply with IPC standards -

Adopt international

Adopt international

Imported equipment -

Instant one-to-one quotation Simple, convenient and time-saving

Instant one-to-one quotation Simple, convenient and time-saving -

Fast proofing speed

Fast proofing speed

High product quality

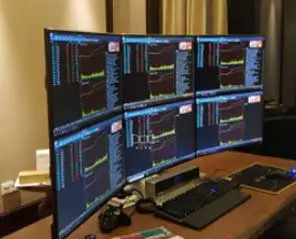

01Use international imported equipment

- The SMT workshop has 2 Panasonic CN88S+ high-speed placement machines, 2 Panasonic multi-function placement machines, 1 reflow soldering unit, 1 wave soldering unit, 1 AOI testing machine, and DIP workshop has 1 automatic plug-in line and post-soldering line*2 2 test assembly lines

0210 years of manufacturing experience

- The plant covers an area of 5,000 square meters. There are more than 100 technical workers and employees for converter R&D and production, and more than 10 hardware/software development engineers to meet the different needs of the market.

- Perfect quality assurance and management system products have passed ISO9001 quality system, ROHS environmental certification, CE, FCC certification, and national 3C certification! TYPE-C HUB docking station products are exported to Europe, America, Japan and other developed countries!

03PCBA one-stop service

- High-quality suppliers, professional procurement, engineering, and production teams, advanced production equipment,Everything is oriented to customer needs.

- ERP material management system, real-time monitoring of material inventory and stocking status, fast line transfer,Fast delivery.